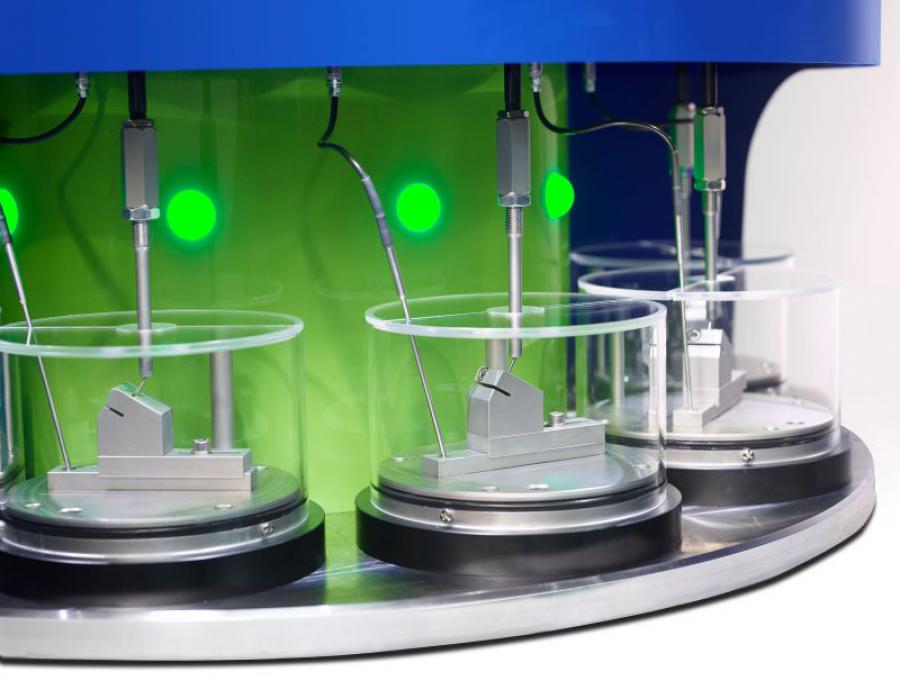

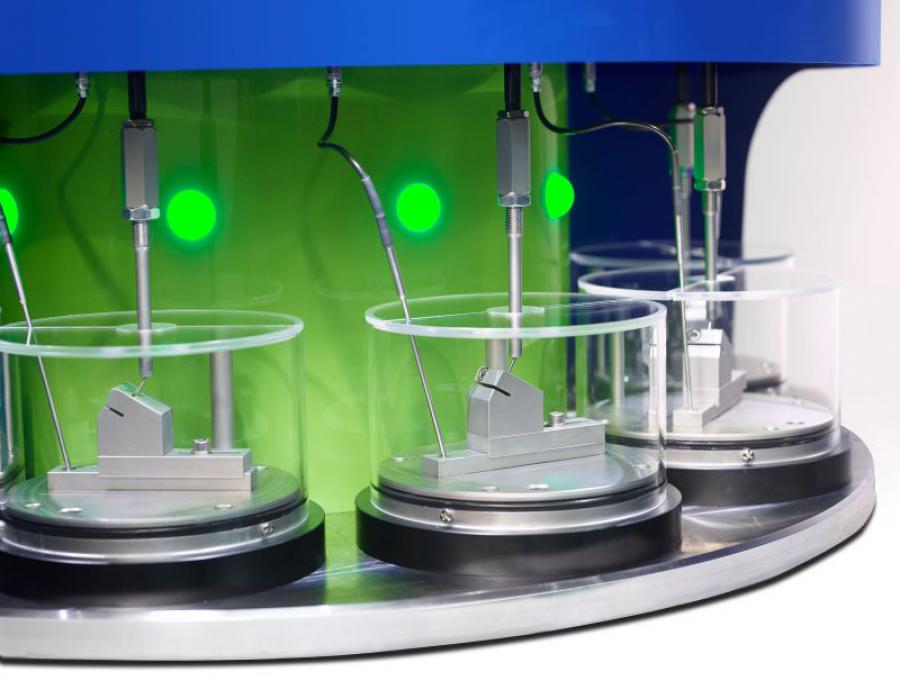

Medical Dental Fatigue Tests

DYNAdent 14801: Testing machine for fatigue tests on dental implants

DYNA-MESS Prüfsysteme offers a machine perfectly adapted for testing dental implants according to ISO 14801.

DYNAdent 14801: Testing machine for fatigue test on endosseos dental implants

Compared to the universal testing machines that are commonly used and only slightly modified, the DYNAdent 14801 testing machine offers many advantages for the specific needs of dental materials:

- Perfectly adapted for the ISO 14801 fatigue test

- Electrically driven. No hydraulic, pneumatic or compressed air is required

- Force measurement unit integrated in the head of the machine for optimal protection and precise measurement

- Displacement sensor also intergrated in the head of the machine for optimal protection and precise measurement

- Compact design

- Convenient visual indication of the operation status (setup, testing, end of test)

- Reservoir for test in liquid solution with fluid circulation and temperature regulation

- Free of lateral force due to a special sliding joint

- Comprehensive software including user administration right management, sample tests library, easy testing parameters setting, online graphic, continous data recording during the entire testing period, test report, ...

- Fixture adapted for straight and / or angled implants

By simply changing the standard fixture for the implant, it is possible to perform other tests like:

- 3 or 4 point bending tests on ceramic rods

- Bending test on bridge structures

- Traction tests

- Compression tests

- ...

Available in two versions

DYNA1dent: Single station machine

DYNA5dent: 5-station-machine

DYNAdent comes together with an all-in-one - PC which can be operated by keyboard as well as by touchscreen.

DYNAdent comes together with an all-in-one - PC which can be operated by keyboard as well as by touchscreen.

For heating and pumping of physiological saline liquid an additional device can be installed.

For heating and pumping of physiological saline liquid an additional device can be installed.

Continuous data recording

By continuously recording data throughout the test period, it is possible to have a statement not only about the type of damages or change in the test parameters but also the evolution of the damages or parameters while performing a test. All data are automatically recorded for further documentation and analysis.

DYNAdent comes together with an all-in-one - PC which can be operated by keyboard as well as by touchscreen.

DYNAdent comes together with an all-in-one - PC which can be operated by keyboard as well as by touchscreen. For heating and pumping of physiological saline liquid an additional device can be installed.

For heating and pumping of physiological saline liquid an additional device can be installed.